Single Core Liquid Filter Housing

| Finish Processing Options | Mech. Polished |

|---|---|

| Polish Quality | Internal: Ra ≤ 0.3 μm; External: Ra ≤ 0.4 μm |

| Shell Options | 304 or 316L stainless steel |

| Drain / Vent Valve | 304, 316L |

| Tri-Clamp | 304 |

| Stabilizer Blade | 304 |

| Seal Materials | Silicone, FKM, EPDM |

| Design Pressure Options | 0.6 MPa (90 psi), 1.0 MPa (150 psi) |

| Max. Operating Temperature | 150 °C (302 °F) |

| Shell-to-Base Connection | Tri-clamp, flange eyebolt |

| Inlet&Outlet | Tri-clamp or flange |

| Vent / Drain Valve | Inner bore, 4mm connects with 8mm pipe |

| Pressure Gauge | 1.5" Tri-clamp (single core); Clamp (multiple cores) |

Single Core Liquid Filter Housing

Multiple Core Liquid Filter Housing

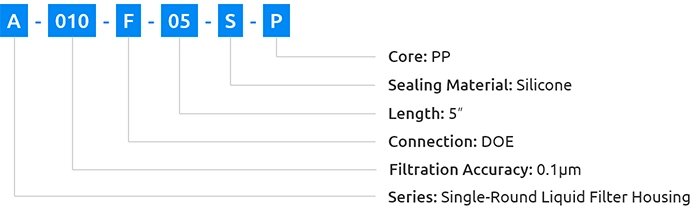

| Series | Filtration Accuracy | Connection | Length | Sealing Material | Core |

|---|---|---|---|---|---|

| A = Single-round liquid filter housing | 010 = 0.1 μm 022 = 0.22 μm 045 = 0.45 μm 065 = 0.65 μm 080 = 0.8 μm 100 = 1 μm 500 = 5 μm |

K = 222 (SS insert) / Fin R = 226 (SS insert) / Fin V = 226 (SS insert) / Flat J = 222 (SS insert) / Flat G = 226 (PSU insert) / Flat F = DOE M = 222 / Flat T = 226 / Flat P=222 / Fin Q = 226 / Fin I = 226 (PSU insert) / Flat |

05 = 5" 10 = 10" 20 = 20" 30 = 30" 40 = 40" |

S = Silicone E = EPDM B = NBR V = FKM F = E-FKM |

P = PP S = SUS |

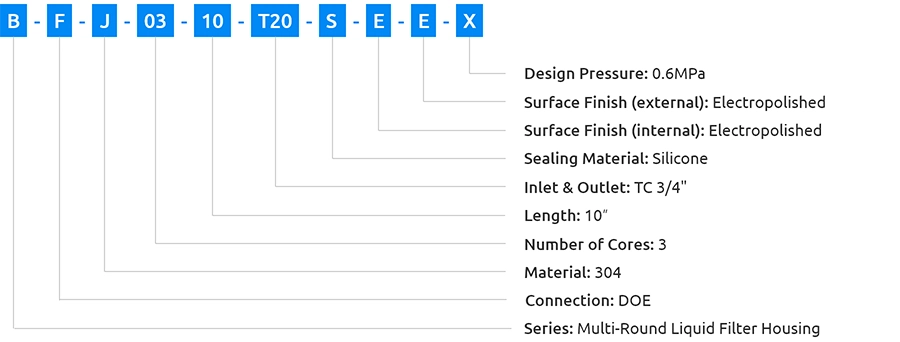

| Series | Connection | Material | Number of Cores | Length | Inlet&Outlet | Sealing Material | Surface Finish (Internal) |

Surface Finish (External) |

Design Pressure |

|---|---|---|---|---|---|---|---|---|---|

| B = Multi-round liquid filter housing | Q = 226 P = 222 F = DOE |

J = 304 K = 316L |

03 = 3 05 = 5 07 = 7 09 = 9 12 = 12 |

10 = 10″ 20 = 20″ 30 = 30″ 40 = 40″ |

T20 = TC 3/4" T20 = TC 1" T30 = TC 1-1/4" T40 = TC 1-1/2" T50 = TC 2" F20 = Flange DN20 F25 = Flange DN25 F32 = Flange DN32 …… |

S = Silicone E = EPDM V = FKM |

E = Electropolished M = Mech. Polished |

E = Electropolished M = Mech. Polished |

X = 0.6 MPa Y = 1.0 MPa |